INTEC K200-FS | the reliable and efficient option for handling chemicals

Everything from a single source - Successful project business in equipping a catalytic world-scale hydrogenation plant (part 2).

Conditions

The INTEC K200-FS ball valve is used in almost all sub-processes of catalytic hydrogenation. These include nitrogen supply to the pulsation damper, outlet control of the filtration unit, amine supply to the combustion chamber, discharge of demineralized water for rinsing and many more. Here the valves are used to control the gaseous and liquid media such as caustic soda, adiponitrile, nitrogen, demineralized water, wastewater (polluted), caustic potash, hexamethylene diamine (HMD), catalyst solutions and catalyst water. The operating conditions of each process range from 1 bar to 33 bar and temperatures from 15°C to 200°C.

Design

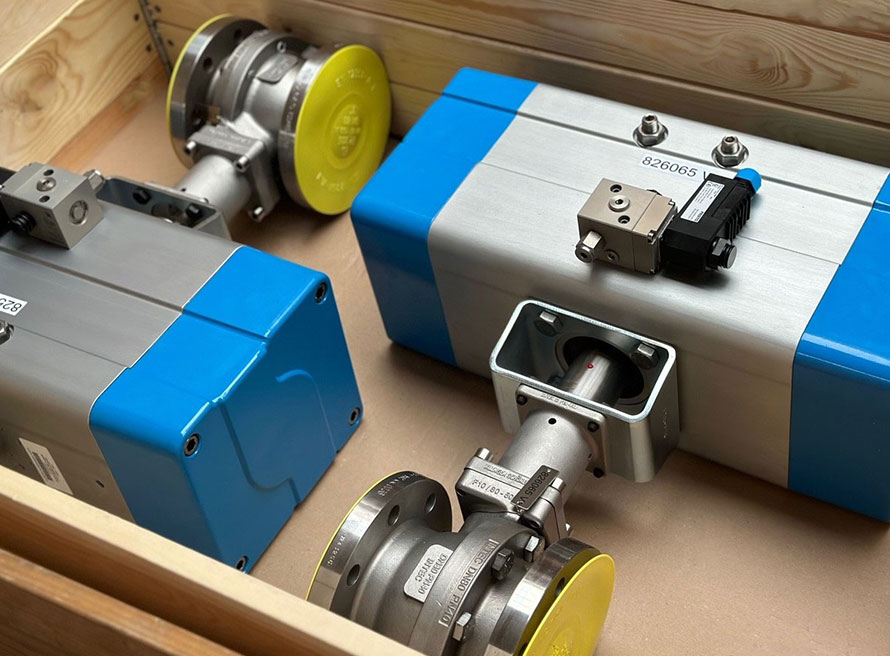

The two-piece flanged ball valve of the INTEC K200 series is the state-of-the-art chemical ball valve with proven design and perfect technical functionality. The ball valves of type INTEC K200-FS in nominal sizes from DN 15 to DN 100, in Fire-Safe design, are equipped with soft-seated ball seat and floating ball.

INTEC K200-FS - two-piece ball valves

Proven design with perfect technical functionality. The ball valves are available in various material combinations and with different features.

- soft seated, wide range of KLINGER sealing materials

- floating ball

- top flange DIN EN ISO 5211, best suited for automation

- approvals acc. to virtually regulations

- wide range of special materials and accessories

- best experiences in the chemical industry are made

Happy to provide you with further information!

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de