Diol plant

Request to blow out superheated steam at 480°C via a ball valve.

In the process of a diol plant (diols are organic compounds containing two alcoholic hydroxy groups, i.e. bivalent alcohols) there is a requirement to blow out superheated steam at 480°C via a ball valve.

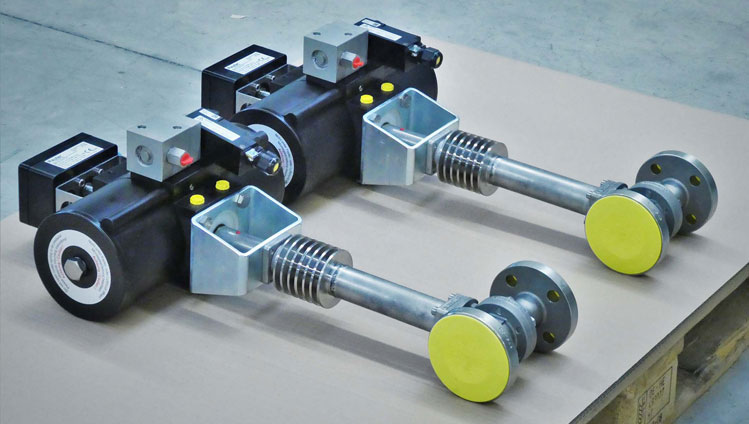

For this purpose, the 2-split body ball valves of the INTEC system technology type INTEC K221-S-HT/11-S DN20 PN40 with a single-acting pneumatic MIG actuator, solenoid valve and limit switch box are used. These are floating and single-spring metal-seated ball valves. The ball and ball seats are carbide coated with chromium carbide nickel/chrome by high velocity oxygen fuel (HVOF) flame spraying.

The 250mm long stem extension is equipped with cooling fins. The cooling fins used to increase the surface area in order to optimize the heat transfer to the environment and thus cooling respective to protect the actuator.

Ball valves INTEC K221-S-HT/11-S DN20 PN40 with a single-acting pneumatic MIG actuator,

solenoid valve, limit switch box and stem extension with cooling fins

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de