Optimized CAPEX and OPEX

Repair of special ball valves proven in operation contributes to optimized CAPEX and OPEX for the customer.

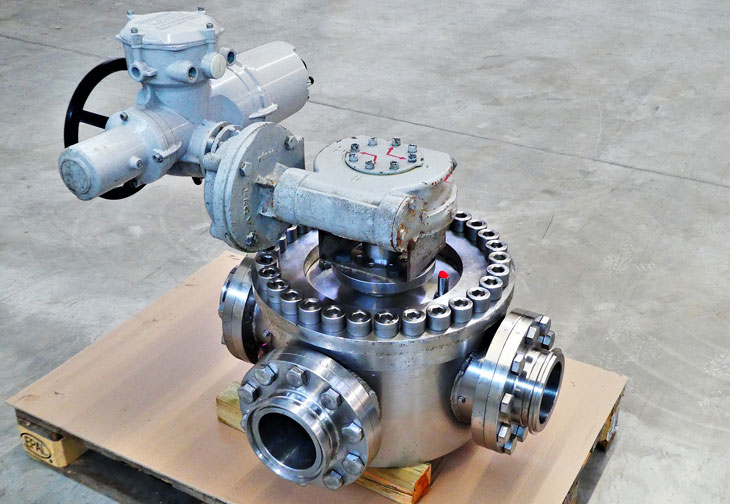

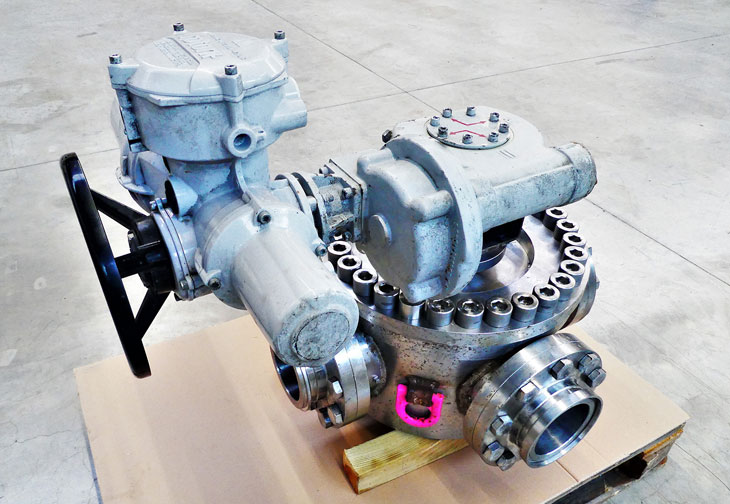

The 4-way metal-seated ball valves are type INTEC K411-S-FMD DN125 PN160 1.4462/SC1/Viton, equipped with an electric actuator type Rotork incl. remote control.

The special features of this design are that

- the body and the ball are made of duplex-material in a welded design,

- the ball has an X-bore,

- the ball ports are realized by pipe elbows and can therefore be piggable,

- the connections are equipped with a quick coupling system (type Zentrifix with spring and groove ring),

- a low dead space design was realized by using of metallic dead space calottes

- and last but not least the spring spaces can be filled with grease by G1/8" connections.

The ball valves are used at Δp of 120 bar and at 70°C in an aggressive and corrosive medium, the so-called thick matter (medium consisting of ash/dust and loose material from waste residue incineration mixed with a magnesium chloride solution). The medium is used to backfill cavities for the purpose of avoiding methane gas bubbles and pit subsidence underground in mines.

Successful repair of special ball valves proven in operation contributes to optimized CAPEX and OPEX for the customer.

4-way ball valves type INTEC K411-S-FMD DN125 PN160 1.4462/SC1/Viton,

equipped with an electric actuator type Rotork incl. remote control.

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de