KLINGER Schöneberg at a glance

More than three decades of experience and more than 16,000 different product designs form the basis for quick response and mutual success ....

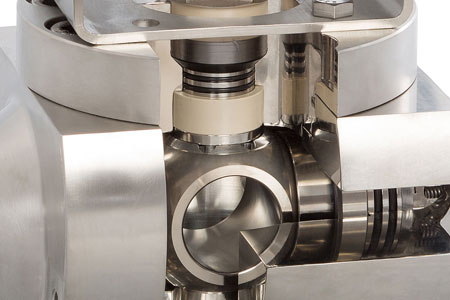

KLINGER SCHÖNEBERG GmbH is a flexible medium-sized company focusing on research, development, production and sales of industrial valves, especially ball valves.

KLINGER SCHÖNEBERG combines decades of experience with a high level of competence in the development of customised system and special solutions as well as providing technical application advice. Within the KLINGER Group, represented at 60 locations worldwide and comprising more than 40 companies, the highly specialised company focuses on critical applications in the chemical, petrochemical, plant and mechanical engineering industries. A wide range of technologies as well as customised solutions are used, including automated solutions for even the toughest conditions. The highest quality, innovative strength, the long lifetime of the products as well as extensive application knowledge and experience make KLINGER Schöneberg a leading company in the field of industrial valves.

The development, production and logistics headquarters is located in Graben-Neudorf, approx. 20 km from Karlsruhe. At the Graben-Neudorf site, the company is situated on an estate with a floor space of 5,200 m² and a building of approx. 4,200 m², comprising an office, warehouse and production hall. Sales, marketing and technical consulting are located in Waldems-Esch im Taunus.

More than three decades of experience and more than 16,000 different product designs are the basis for quick responce and mutual success.

Quality is not just a piece of equipment, but a product feature we guarantee!

What customers can expect from us?

More safety, quality, reliability, lifecycle, availability and sustainability - with the innovative and proven products from the INTEC system technology, plant operators get more out of their process plant.

We combine engineering expertise with development experience, application knowledge and services to provide you with the optimum product solution using INTEC system technology for shutting off, controlling and influencing your fluid and gaseous mass flows in your process lines and plants.

Industrial valves are important components for maintaining transport and production processes in the process plants of all industries. Their scope of operation ranges from shutting off, throttling and controlling material flows in piping systems to opening and closing processes in piping systems. The sometimes-extreme operating conditions such as high pressures, extreme temperatures as well as aggressive, abrasive, corrosive and toxic media and the safety requirements in process and control engineering require individual and innovative products combined with detailed technical knowledge and application experience for the differentiated design, development and manufacture of industrial ball valves.

- Everything from one, single source.

- Everything for an optimized CAPEX and OPEX.

- Everything with the INTEC system technology.

Added value for the customers

- Long product life

- High product quality

- High level of application experience

- Product innovations

- Intensive pre-qualification of prototypes under realistic conditions before use

- Products developed specifically for customers

- High level of development expertise

- Listed supplier with all major chemical customers

- Extensive knowledge and experience in the application of standards and regulations

- More than 16,000 different ball valve designs

- Reduced CAPEX and OPEX

Unique selling points

- Metal-seated ball valves - absolutely gastight (Leakage class VI)

- Ball valves with great tightness of the gland packing to limit fugitive emissions

- Ball valves for high temperature applications (up to 800 °C)

- Ball valves for high pressure applications (up to 400 bar)

- All ball valves with unique spring-loaded gland design

- All ball valves (soft or metal seated) are also vacuum-tight as standard

- Diverse solutions for safety-relevant and critical applications

- Ball valves available in all available special metallic materials

See for yourself !

Certificates and Approvals

- Quality-Management acc. to DIN EN ISO 9001:2015

- Certified acc. to API 6D

- PED 2014/68/EU,Module H

- WHG §19a approval (water-resources law)

- Allowance for the re-stamping of products by TÜV

- CRN certified for all regions of Canada

- TTC (TSG) - Chinese Type Test Certificate

- Manufacture License, SELO (China)

- EcoVadis Sustainability Rating - Gold Award