Duoball INTEC K200-FS | with double shut-off, especially for applications with extremely high safety requirements

Everything from a single source - Successful project business in equipping a catalytic world-scale hydrogenation plant (part 8).

Conditions

In addition to influencing the fluid or gaseous mass flows in the hydrogenation process, valves are required for the safe shut-off of pipelines and thus fulfill an essential safety function. For this reason, there are high safety requirements when handling critical media such as hydrogen, which are also always an integral part of plant safety.

Design

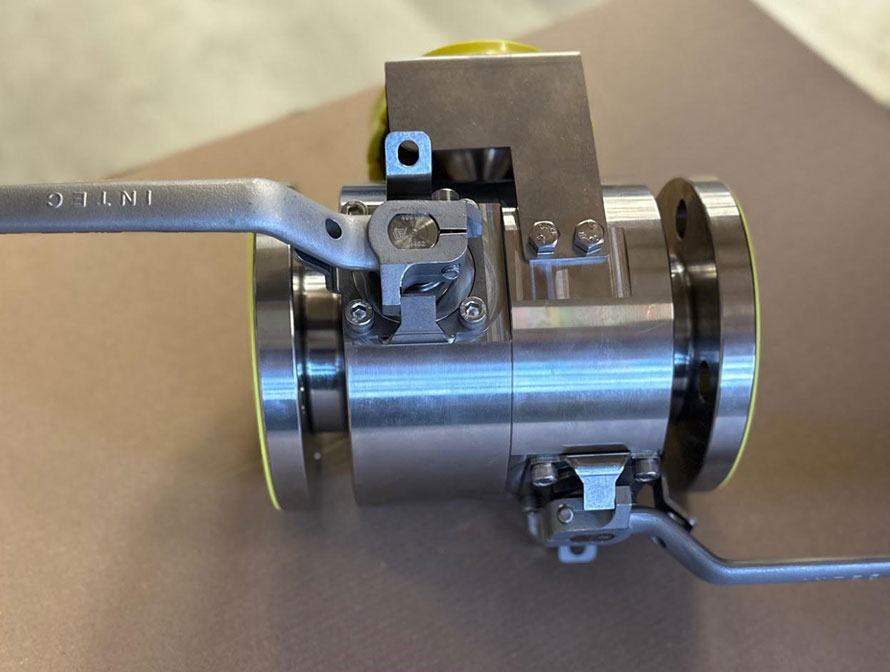

The used INTEC Duoball K200-S-FS in floating and soft sealing design, has a double and independent shut-off with a pneumatic automation unit. This can significantly increase safety compared to standard ball valves. The design is based on the integration of two ball valves in one body in the standardized overall lengths according to EN 588 R1 with the smallest possible gap.

The intermediate piece of the INTEC Duoball was equipped with two opposite outlet flanges of nominal size DN15 and pressure rating PN40. This provides the operator with the options of leakage and pressure monitoring, pressure relief, flushing and nitrogen overlay of the interstitial space as well as temperature control of the interstitial space.

INTEC Duoball ball valve

Ball valveswith double shut-off, especially for applications with extremely high safety requirements.

- double and independent shut-off

- compared to standard ball valves, safety is significantly increased

- the design is based on the integration of two ball valves in one body

- like all ball valves of the INTEC series, the Duoball valve is available with floating ball or trunnion mounted ball as well as soft or metal seated execution

- all ball seat systems naturally fulfil the leakage rate A according to EN 12266 and are absolutely gas-tight

- due to the double insulation and venting function, every duoball valve is bi-directionally tight

- the Duoball valve is also available in the standardised overall length according to EN 588 R1

- in addition to increasing safety, offers a compact and cost-effective alternative to using several standard valves

Happy to provide you with further information!

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de