Ethylene oxide (EO)

Critical applications in connection with toxic and hazardous media require particularly reliable shut-off and protection.

This is especially true for applications in the medium ethylene oxide (also called EO), which

- is a colourless, highly flammable gas with a high exothermic reaction, especially in contact with water, alcohol, ammonia, acid, bases and rust

- boils at 10.5°C and is highly toxic and carcinogenic.

- serves as an important intermediate in the production of other chemicals for end products such as solvents, dyes, fertilisers, plastics, silicone, etc.

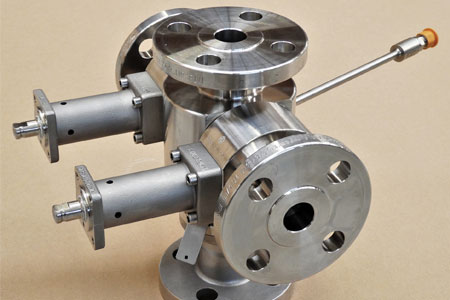

Connected to the EO reactor are two ball valves type INTEC K220-S-FS-DE-DB arranged in series as a double-block shut-off in design as floating ball valves with spring loading on both sides and automatic pressure relief in the dead space of nominal size DN 1" and pressure Class 300. The so-called bleeding ball valves, also two ball valves arranged transversely to the axis in design as floating ball valves type INTEC K200-S-FS-DB of nominal size DN ¾" for the barrier with nitrogen.

In the plant, a pressure transmitter is installed on one side and a integrated and welded temperature transmitter in the middle part of the body for monitoring. The entire unit is made of stainless steel material 316L and specially designed for minimised product and gas quantity respectively for safety reasons.

INTEC K220-S-FS-DE-DB DN1“ – ¾“ – 1“ red./11

Cl.300 RF WE 316L/KFCM – free of oil and grease

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de