Filling of special lubricants

Process for filling special lubricants at a tank.

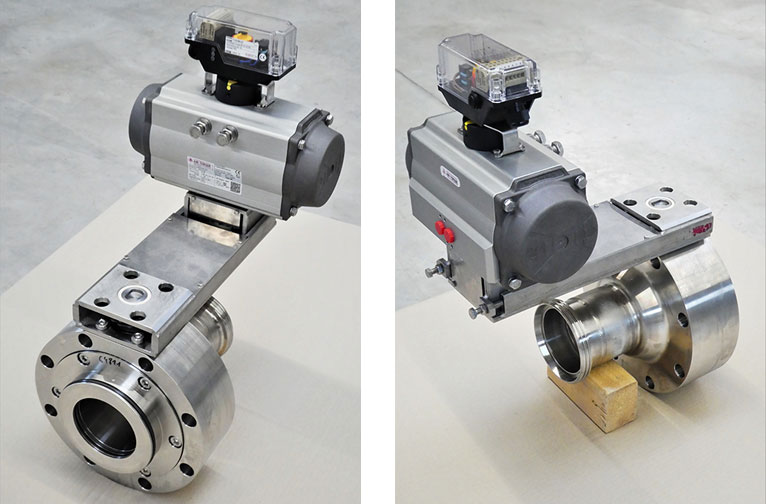

In the process for filling special lubricants at a tank, the tank bottom ball valve type INTEC K500-S-STD with pneumatic actuator and end position feedback in nominal size DN150/100 and pressure rating PN10 made of material 1.4404 is used.

This tank bottom ball valve is a floating version with a ball-seat made of KFGN (KLINGER Flon glass fibre nitrogen sintered) spring-loaded on one side. The tank connection is according to DIN 28117 and the pipe connection with a so-called milk pipe fitting.

Due to the confined space under the tank, the actuator was relocated to the outside by means of an adjustable chain drive.

Tank bottom ball valve type INTEC K500-S-STD DN150/100 PN10 material 1.4404

with pneumatic actuator, milk pipe fitting, chain drive.

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de