Quartz sand

Incineration of municipal and industrial sludge in fluidized bed furnaces.

Successful reconditioning of service-proven metal-seated ball valves for high-temperature applications contributes to optimized CAPEX and OPEX for the customer. Municipal and industrial sludges are incinerated in a fluidized bed furnace (incinerator).

The quartz sand used in this process keeps the material to be incinerated in motion. To discharge the quartz sand, ball valves INTEC K231-S-HT-FM/11-S of nominal size DN100 and pressure rating PN16 with a stem extension are used. The discharge of the very abrasive quartz sand takes place at a slight negative pressure and at temperatures of 700°C to 800°C.

Features of the ball valve

- trunnion mounted design with spring-loaded ball seat on one side and a free outlet on the other side (absolutely free of dead space and unobstructed media outflow)

- ball and ball seats are manufactured with hard metal coating of chromium carbide nickel/chromium using the HVOF process (High Velocity Oxy-Fuel spraying)

- body is made of high-temperature material 1. 4828 (stainless heat-resistant austenitic chromium-nickel steel)

- spring chamber of the ball seat is sealed

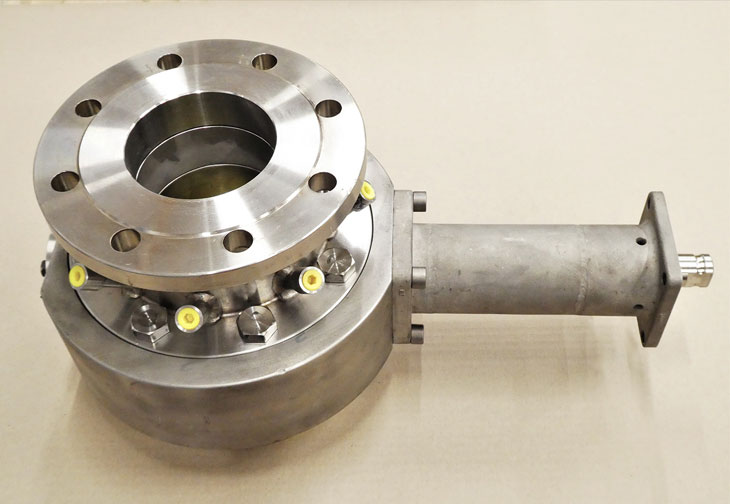

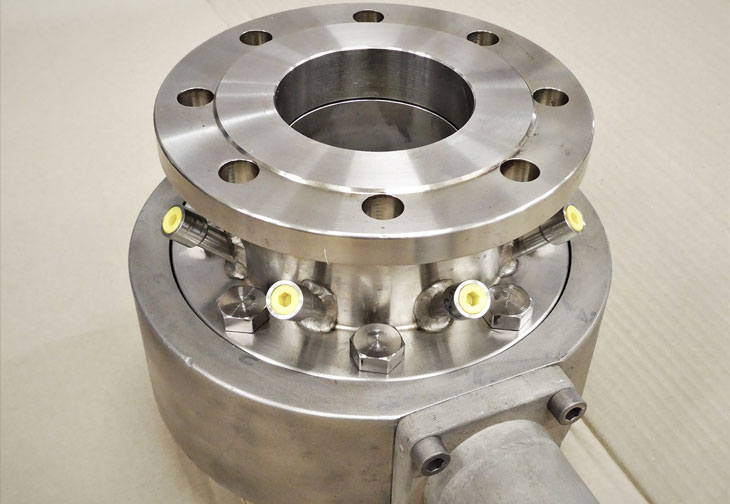

Ball valve INTEC K231-S-HT-FM/11-S, nominal size DN100, pressure rating PN16, material 1.4828,

with stem extension

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de