Reconditioning of high-pressure ball valves

Reconditioning of operationally proven high-pressure ball valves contributes to optimized CAPEX and OPEX for the customer.

Successful reconditioning of operationally proven high-pressure ball valves contributes to optimized CAPEX and OPEX for the customer. In the chemical industry, the process of hydrogenation plays an important role in the production of various raw products for Amine.

Hydrogenation is the addition of hydrogen to other chemical elements or compounds. It is usually carried out at elevated temperatures (up to 500°C) and pressures (up to 250 bar) and in the presence of catalysts (catalytic pressure hydrogenation).

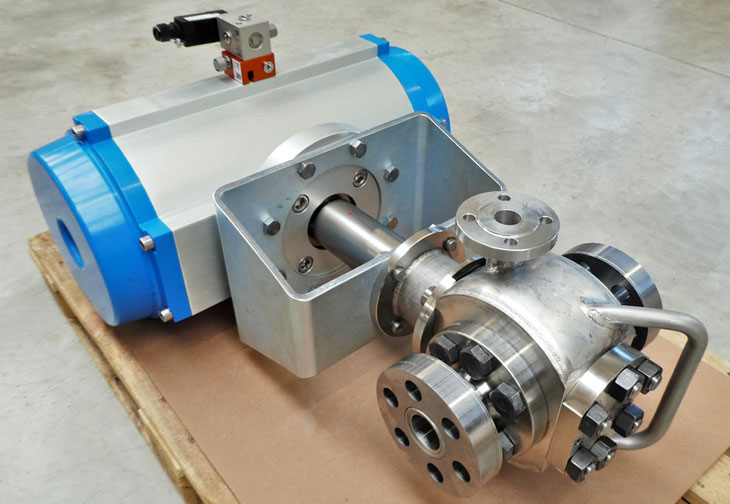

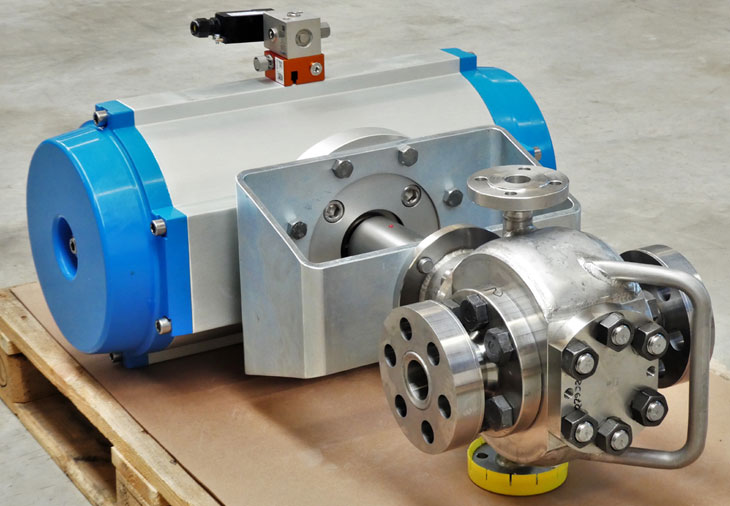

For this demanding process and the required plant safety, particularly reliable high-pressure ball valves are needed. For this purpose, the well-proven 3-split body ball valves of the INTEC system technology type INTEC 117G-S-HT/11 (equal to INTEC K811) are used.

These are metal-seated trunnion mounted ball valves, spring-loaded seats on both sides and pressure rating PN325. The body material of RA4 and the pipe connection by means of screw flanges and lens seal comply with the high pressure guideline. In addition, the ball valves are equipped with a heating jacket of pressure rating PN40 and a stem extension.

The design feature is that the stem, ball and the bearing trunnion are one-piece made of Superduplex material and coated with a nickel-based hard alloy by thermal spraying with subsequent melting down non-porous hard material, as well as the ball seats.

Ball valve INTEC 117G-S-HT/11 (equal to INTEC K811), nominal size DN45, pressure rating PN325,

body material RA4, with heating jacket, stem extension and actuator

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de