Tandem-3-way ball valve

for cooler changeover of a compressor. Ensuring continuous and safe plant operation.

Air separation plants produce oxygen, nitrogen, argon and other noble gases in a highly purified form, which are required for production in the chemical and steel industry, for example. This is done by a combination of adsorption purification, cryogenic distillation and internal compression of high-pressure products.

In order to maintain constant production and avoid damage to the plant components during load changes due to start-up and shut-down of the plant, the KLINGER Schöneberg tandem 3-way ball valve ensures a continuous supply of cooling to the compressor.

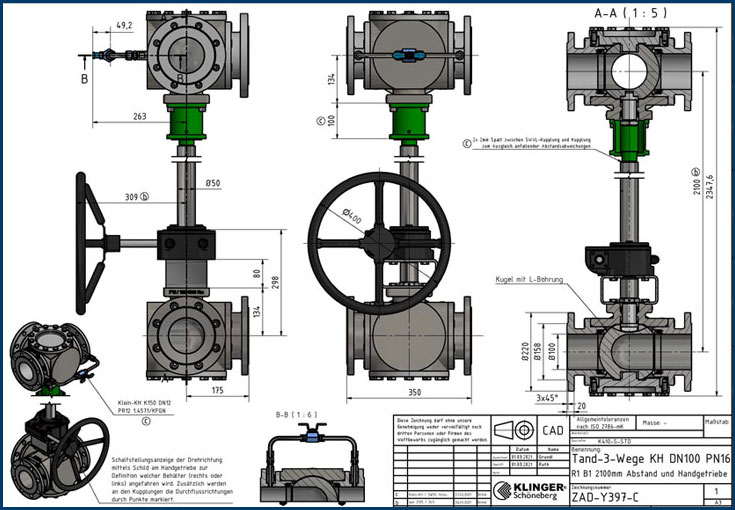

The tandem 3-way ball valve type INTEC K410 with L-bore DN100 PN16 has a coupling that connects both valves at a distance of approx. 2.1 m. The customized special design has an adjustment to compensate for distance deviations. This allows both valves to be actuated for cooler changeover with only one mounted manual gearbox. This requirement is a result of the customer's request, since it is necessary to shut off the cooling via the one 3-way ball valve during operation and open the second 3-way ball valve at the same time, in order to be able to carry out the inspection work without danger and without causing a plant shutdown. In addition, one 3-way ball valve has a bypass, which can be operated with an ball valve type INTEC K150 DN12 PN160 for pressure equalization.

Tandem-3-way ball valve INTEC K410-L-S-STD/11-S DN100 PN16 R1 B1

with stem extension and mounted manual gearbox.

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de