Thermal shock

In the production of catalyst converters, a high-temperature powder is mainly produced.

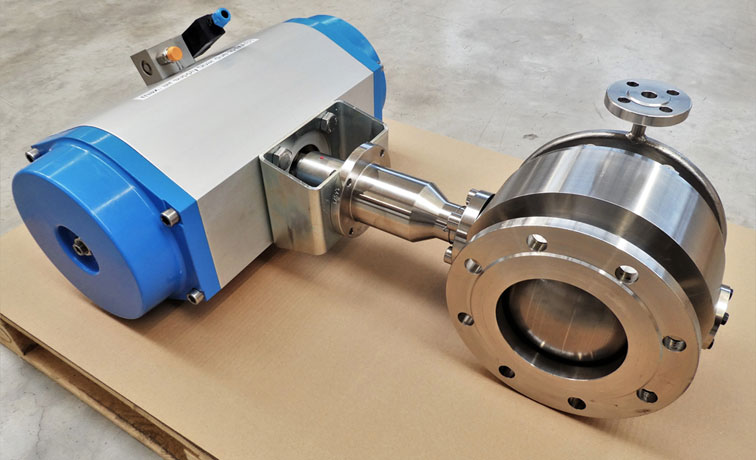

In the production of catalyst converters, a high-temperature powder is mainly produced. For this purpose, INTEC K231-S-HT-FM/12 metal-seated ball valves of nominal size DN150 and pressure rating PN16 in face-to-face length R1 made of material 1.4571 with pneumatic actuator are used on the reactors.

When the ball valves are opened, they receive a thermal shock. Therefore, the ball valves are designed for an operating temperature of 540°C and an operating pressure of 3 bar.

The special features of this design

- the ball valves are in trunnion mounted design

- with a spring-loaded ball seat on one side and a free outlet on the other side

- the ball and ball-seats are made non-porous with a cobalt-based hard alloy by thermal spraying with subsequent melting

- the ball-seat is equipped with a stripping edge

- the spring chamber is sealed

To eliminate possible media accumulation on the ball and the ball seat during operation, an integrated ring flushing line was implemented on the inlet flange. This prevents negative effects on the actuating torque. In addition, a 200 mm INTEC 12 stem extension with an additional stuffing box packing was used.

Ball valve INTEC K231-S-HT-FM/12, metal seated, nominal size DN150, pressure rating PN16,

face-to-face-length R1, material 1.4571, with pneumatic actuator

Your contact

- Marcel Gossmann, Business Development Manager / Management Assistent

+49 6126 950 - 268 marcel.gossmann@klinger-schoeneberg.de